LED Grow Light Fundamentals

An ongoing series on selecting, deploying and using LED grow lights

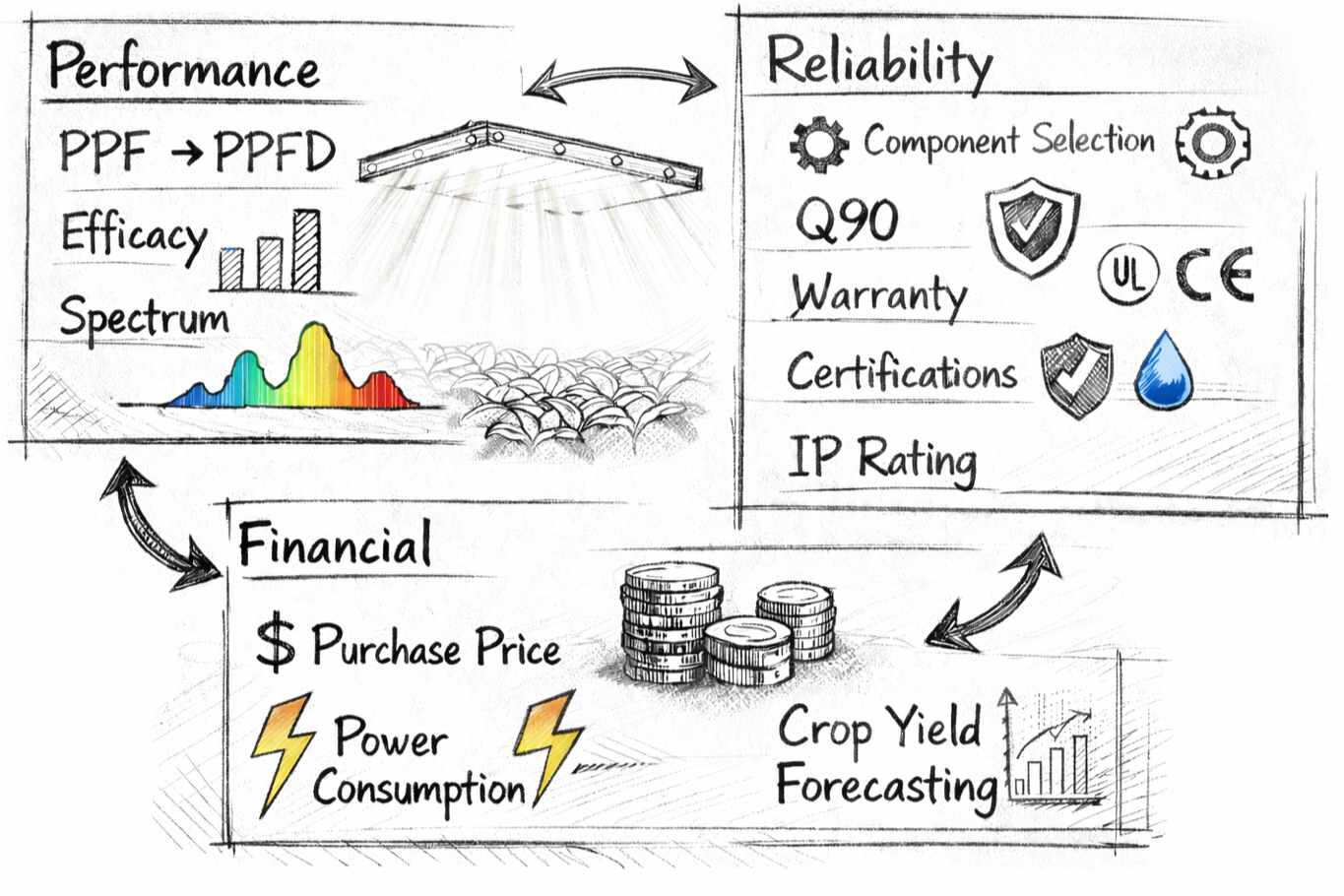

Choosing the right grow light depends on more than just performance metrics, new features or even price. It’s a major financial decision that stays with your business for years. When considering options, you aren’t just deciding on a fixture; you’re managing a dozen variables that directly influence crop production and ROI:

Performance metrics like PPF (and how it is delivered as to your canopy as PPFD), efficacy and spectrum.

Reliability metrics like component selection, Q90, warranty terms, certifications, and IP rating.

Financial metrics like purchase price, power consumption, and crop yield forecasting.

Between the technical jargon and the sales pitches, it’s easy to get lost. We’re starting this series to simplify things and break down each of these topics in a practical, approachable way (and be sure to visit our LED Grow Lighting Glossary for a clear reference to the terms and metrics used throughout this article).

We have found the best lighting decisions come from a strong foundation – especially when comparing options across different vendors. As an engineering services firm, our goal is to provide the optimal horticulture lighting solution for your facility and your business based on real constraints and real performance – not just a marketing feature list.

Once the fundamentals are clear, it becomes easier to evaluate options with confidence, ask better questions, and make purchase decisions that hold up over time. You won’t find a one-size-fits-all “right answer” in this series, because every farm is unique. The best lighting strategy depends on your crop, environment, goals, and operating constraints.

Before we get into the nuances (and the tradeoffs between things like efficacy, cost, and spectrum), it helps to start with the basics.

So first, we ask:

What is light, and how do plants use it?

At the most fundamental level, light travels in tiny packets of energy called photons. Each photon has a wavelength, measured in nanometers (nm), which relates to how much energy it carries. In general, shorter wavelengths carry more energy than longer wavelengths.

Humans can only see photons with a wavelength between roughly 400 nm to 700 nm which we call visible light. Within that range, we perceive different wavelengths as different colors:

400–500 nm: blue

500–600 nm: green

600–700 nm: red

Plants interact with this same bandwidth of light (referred to as Photosynthetically Active Radiation or PAR) through specialized structures called photoreceptors. These photoreceptors absorb photons and help plants turn light energy into chemical energy used for growth and development. While different photoreceptors have their own absorption bands (meaning they’re more likely to absorb certain wavelengths), leaves contain a mix of light-absorbing pigments and receptors that allow plants to use all PAR photons for photosynthesis.

This context is useful because spectrum is often one of the most heavily marketed features in horticulture lighting. And while spectrum absolutely matters for many plant responses, it’s also helpful to keep one core concept in mind when you’re thinking specifically about photosynthesis:

photons between 400–700 nm are counted equally.

Even though a 400 nm photon contains more energy than a 700 nm photon, the plant generally doesn’t “bank” that extra energy for additional growth. Any excess energy above what’s needed for photosynthesis is typically dissipated (often as heat), so the outcome per absorbed photon tends to be similar.

So what tends to matter more in a commercial facility: light quality (spectrum) or light quantity (PPF)?

In many real-world commercial environments, PPF is often the bigger driver of results than fine-tuning spectrum. A practical way to think about it is:

More intensity with a “good enough” spectrum will often outperform lower intensity with a highly optimized (or tunable) spectrum.

That doesn’t mean spectrum doesn’t matter - it can meaningfully influence important factors like plant morphology and crop steering, but as a general rule, spectrum strategies tend to work best when they don’t come at the expense of delivering more total energy (photons) for growth.

In other words, if you are choosing between:

light energy (PPF), or

light quality (spectrum),

…most growers will see better results (and better economics) by prioritizing light energy first.

This is just a Primer, and photobiology gets deep quickly – there are plenty of nuances, exceptions, and crop-specific considerations. We’llget into more of that in our “Advanced” primer later in the series. For now, these fundamentals give a useful baseline for evaluating fixtures and lighitng plans in a way that maps to what actually drives performance: balancing the variables that matter in the real world, for your facility, your crop, and your business.

In our next Primer, Verifying & Comparing Lighting Designs, we’ll shift gears and focus on how to validate lighting designs and proposals from multiple vendors—along with an apples-to-apples approach to calculating, measuring, and verifying PPFD.